OVERVIEW

- Suitable for scaling soft and delicate dough

- Divider does not overwork the dough

- Suction cutting system:

- Does not squeeze the dough

- Sucks up and expels the dough

- Closed lubrication circuit with oil recovery and filtering

- No daily cleaning operations required

- Adjustable automatic flour duster

- Recommended for use with automatic production lines

WEIGHT ADJUSTMENT

- Electrical device with display on control panel

- Manual adjustment with flywheel at the back of the divider

- Weight adjustment via PLC controlled touchscreen

CONSTRUCTION & MATERIALS

- Stainless steel hopper with optional Teflon coating on the inside

- Main chassis made of steel

- Dividing drum made of chrome-plated steel

- Piston chamber made of stainless steel

- Anticorrosive piston

- Covers made of stainless steel

OPERATIONAL FEATURES

- V2 model works in 2 parallel rows

- Optional patented doubling system for double-size pieces

- Larger hoppers available upon request

- AC inverter is standard

- Optional dough twisting system

- Counter and On/Off button for flour duster

- 24V control board

- Easy motion operation

- Piston stops at discharge position when the machine stops

- Motor power transfer via pulley and belt system

- Standard hopper capacity: 70kg, optional 140kg hopper

BENEFITS

- Quick Delivery: Your machine arrives at your doorstep hassle-free.

- Easy Setup: Our experts ensure your machine is ready for production without any complications.

- Personalized Training: Gain confidence in operating your machine through tailored training sessions.

- Proven Recipes: Access a range of tested recipes for top-notch product quality and efficient manufacturing.

- Continuous Support: Our dedicated technical team is always ready to assist, ensuring your machine operates smoothly.

- Fast Parts Delivery: Get machine parts delivered promptly for uninterrupted production.

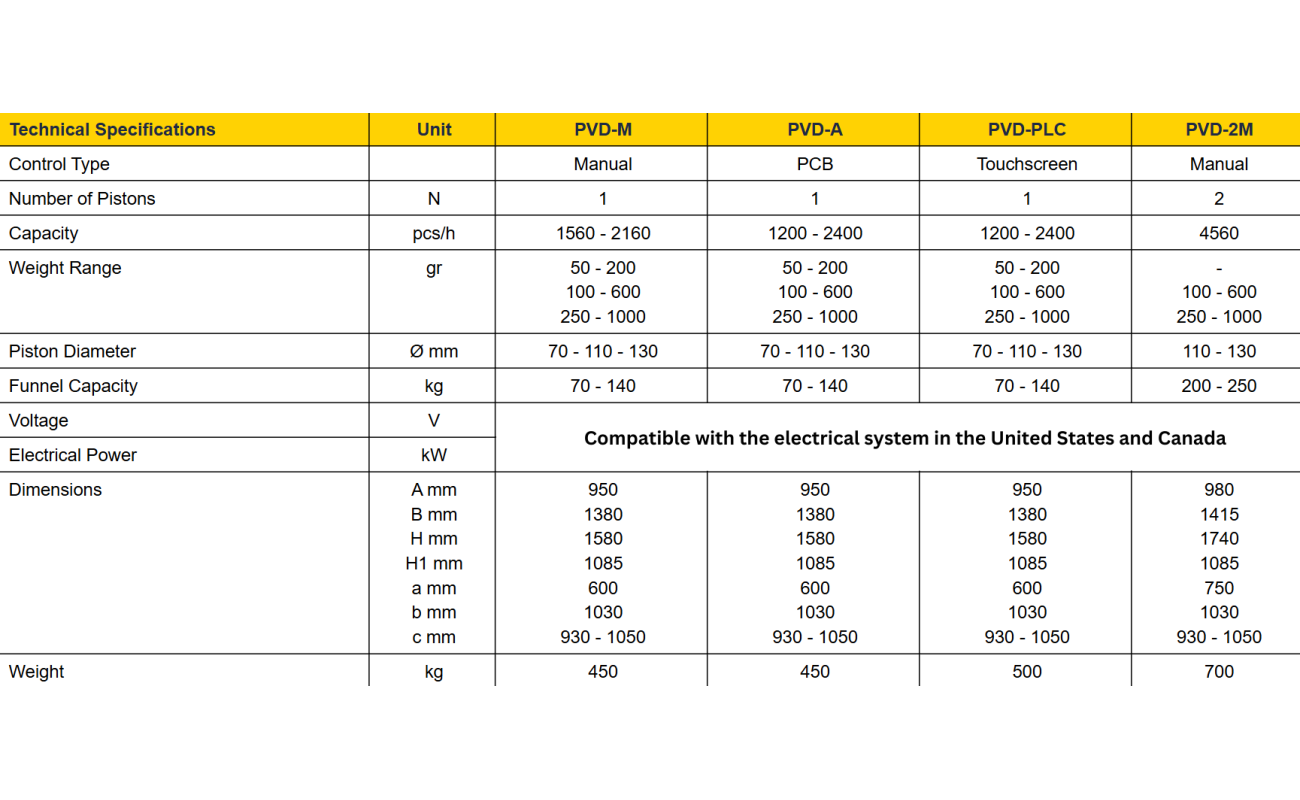

TECHNICAL SEPCIFICATION

PRODUCT APPLICATIONS

Perfectly Portioned Dough Pieces

- Achieve consistent, precisely weighed dough pieces ranging from 100-600 grams, ideal for a variety of baked goods.

- Ready for Baking: The dough pieces are perfectly portioned and ready to be used for making bread, rolls, pizzas, pastries, and other baked products.

- Maintained Dough Integrity: The cutting process ensures that the dough remains soft and airy, retaining its quality and texture for superior end products.

- Versatile Baking Applications: These dough pieces can be used in both artisanal and commercial baking, providing flexibility for creating a wide range of baked items.

- Efficient Production: The machine's high-speed cutting capability ensures a steady supply of dough pieces, keeping up with the demands of high-volume baking environments.

- Consistent Quality: Each dough piece is cut to the same weight and size, ensuring uniformity in the final baked products, which is crucial for professional baking standards.

- Hygienic Preparation: The stainless steel construction ensures that the dough pieces are prepared in a clean and sanitary environment, ready for further processing or baking.

Previous

Next